Monday, November 20, 2017

Purchase Info Record & Source list

Purchase Info Record

Info record is short form for purchase

information record. The info record contains concise information about a vendor

and a material that purchasing already procures from that vendor. An info

record thus represents a material-vendor relationship.

Purchasing info record shall be updated while processing various

purchase documents like contract, imports, etc.

The details shall be maintained for a plant and purchasing organization.

Details like prices & other conditions, the information in the latest

purchasing info record for a combination of vendor and material for that

purchasing organization and plant shall always be defaulted when creating a

purchase order. Info record will be maintained from the last PO number in the

combination of vendor and the material.

Source List

A source

list specifies the possible sources of supply for a material over a given

period of time.

It shows the time period in which a material

may be ordered from a given vendor or under a certain long-term purchase

agreement. The source list supports the user in answering the question: “Which

vendors or internal suppliers can supply a material at a given point in time?”

It is also used in the automatic selection of vendors for a material. The

source list record uniquely identifies the source of supply, a vendor, an

internal plant, or an outline agreement item, and facilitates determination of

the applicable source for a purchase requisition at a certain time

·

Source List can be created automatically or manually

You

can maintain the fixed source of supply in source list

·

You can block the vendor for the specific time period for a specific

material

Vendor Master Data

Vendor Master Data

Vendor Master

This is the enterprise main source of vendor

specific data. This data will include information on vendors

from which a company can procure or it can sell. Vendor Master Record will

contain necessary information of vendors like vendor's name, address, bank

account details, etc.

Vendor Account Groups

Vendors are categorized

according to requirements and some of the vendors having similar

characteristics are grouped together and placed in one category.

For Example: import vendors, domestic vendor,

etc.

Types of Vendors

1.

Internal Vendor:

Supplying by another Plant / Company Code under the same Client.

2.

External Vendor: A company who supplies the materials from

outside.

3.

One time Vendor:

Supply materials only once.

4.

Regular Vendor:

Supplies the materials at Client level.

Vendor Creation

Vendor can be created at Purchasing Department

level and Accounting Department level or at Central level.

Material Creation

Material Creation

Path

SAP Menu-Logistics-Materials Management-Material Master-Material-Create.

T-Code: MM01

1. Select Industry Sector

2. Material Type

3. Select Views:

- Basic Data 1 & 2

- Purchasing

- General Plant Data / Storage 1

- Accounting

Basic Data

- It is maintained at Client Level

- In this view enter Material Number

- Material Description

- Unit of Measure

- Material Group

- Weight

- Volume ...etc

Purchasing

- It is maintained at Plant Level

- In this view enter Purchasing Group details..etc

General Plant Data / Storage

- it is maintained at Plant & Storage Level

- Provide details of Plant & Storage Locations.

Accounting View

- It is maintained at Plant Level

- Currency Check

- Valuation Class

- Price Control if Standard enter Standard Price, if Variant then enter Moving Price.

Material Master Data Configuration

Material Master Data Configuration

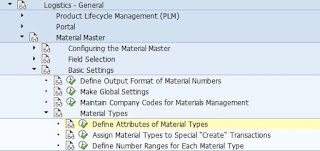

Define Attributes of

Material Types

Menu path Implementation Guide for R/3

Customizing (IMG) ® Logistics - General

Material Master Basic Settings Material Types Define Attributes of Material Types

Transaction Code: OMS2

While creating Material Type we need Account Category Reference.

Account Category Reference:

- It is group of Valuation Classes.

- It link Material Type & Valuation Class

- It uses to check whether the valuation class you have entered is allowed when you maintain accounting data.

|

Material Types

|

|

|

S.NO

|

Type

|

|

1

|

Raw Material

|

|

2

|

Semi finished

|

|

3

|

Finished

|

|

4

|

Trading

|

|

5

|

Service

|

|

6

|

Packing

|

|

7

|

Scrap

|

|

8

|

Non-Valuated

|

|

9

|

Spares

|

Define Number Ranges for

each material types

Menu path: Implementation Guide for R/3

Customizing (IMG) ® Logistics - General

Material Master Basic Settings Material Types Define Number Ranges for each

Material Types

Transaction Code: MMNR

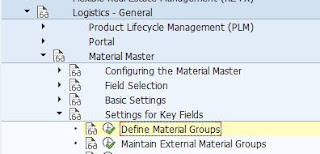

Define Material Groups

Menu

path: Implementation Guide for R/3

Customizing (IMG) ® Logistics - General

Material

Master Settings for

Key Fields Define Material

Groups

Transaction Code: OMSF

Material Master Data

Material Master Data

Material type

Materials with the same basic attributes are grouped together and

assigned to a material type. This allows management of different materials in a

uniform manner in accordance with the company's requirements.

Examples of

material types are:

1. Raw material

2. Semi finished

3. Finished

4. Spares

5. Scrap

6. Non-Valuated...etc

Number Range for Material Type

b

When we create material master record every material is recognized by a number, that number will be unique and known as MATERIAL NUMBER.

Material Group

Material

groups are used for reporting purpose. You can execute and see the different

reports like purchasing values, purchasing quantities, stocks, receipts,

issues, and inventory turnover, etc. on the basis of material groups.

Material Creation

After completion of above steps we can create a new material.

Master Data

Master Data

Data that is created centrally and it is valid for all applications. It remains constant over the time but we need to update it on regular basis.

Material Master Data

The

material master contains information of all the materials that a company

procures, produces, stores and sells. It is the company’s central source for

retrieving material-specific data.

The

integration of all material data in a single database object eliminates

redundant data storage. The data contained in the material master is required,

for example, for the following functions:

§ In purchasing

for ordering

§

In inventory management for

goods movement postings and physical inventory

§

In invoice verification for

posting invoices

§

In sales and distribution for

sales order processing

§

In production planning and

control for material requirements planning, scheduling, and work scheduling

The following figures

display the structure of the material master records.

·

Basic data

·

Classification

·

Purchasing

·

Purchasing order text

·

Sales

·

Sales text

·

MRP

·

Work Scheduling

·

General Plant Data / Storage

·

Warehouse Management

·

Quality Management

·

Accounting

·

Costing

·

Plant Stock

·

Storage Location Stock

It is a Master file which contains information of a particular material,

depending upon the views selected from the user departments.

Enterprise Structure Assignment

Enterprise Structure Assignments

Assign Plant to Company Code

Menu path: Implementation Guide for R/3 Customizing (IMG) ® Enterprise Structure

®

Assignment ® Logistics general ® Assign Plant to Company Code

Transaction Code:

OX18

Assign purchasing organization to

company code

Menu path: Implementation Guide for R/3 Customizing (IMG) ® Enterprise Structure

® Assignment ® Logistics general ® Assign purchasing organization to

company code

Transaction Code:

OX01

Assign purchasing organization to

Plant

Menu path: Implementation Guide for R/3 Customizing (IMG) ® Enterprise Structure

® Assignment ® Logistics general ® Assign purchasing organization to

Plant

Transaction Code:

OX17

Subscribe to:

Comments (Atom)